Barry Hayes, owner of UK Sailmakers Ireland, describes new advances in 3D sail design programmes to analyse sail shape and sail design in real time. In this latest article in the UK Series, in association with ICRA, Hayes outlines the Sailpack programme, the preferred tool of UK Sailmakers Ireland.

Once upon a time sail design was akin to a black art. The sailmaker, a whiskery gent with scarred thumbs and a keen eye for a curved line, took a long hard squint at your boat and your rig, weighed up a ton of variables (as a artisan craftsman should), and made a sail that was the compound product of experience and imagination.

Then along came CAD programmes, and the sailmaker quickly came to rely less on intuition and more on proven numbers. There were still hand drawn files, to be sure, but now the designer had the ability to model a sail’s shape and test its performance characteristics on a computer screen, rather than going through time-consuming and expensive wind tunnel testing. Building two full size sails, each one a little different, was no longer necessary in order to test developmental ideas.

Now say hello to 'Sailpack', the very best sail design programme of all, and the preferred tool of UK Sailmakers Ireland. As the saying goes, “this changes everything.”

Sailpack comes with a full complement of 3D design and fluid dynamics modelling tools. It not only takes away the nth degree of guesswork from the design process; it allows you, the customer, to see what’s going on in the design process.

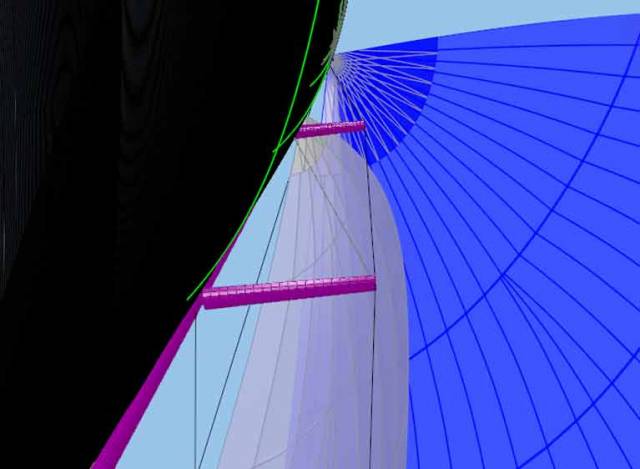

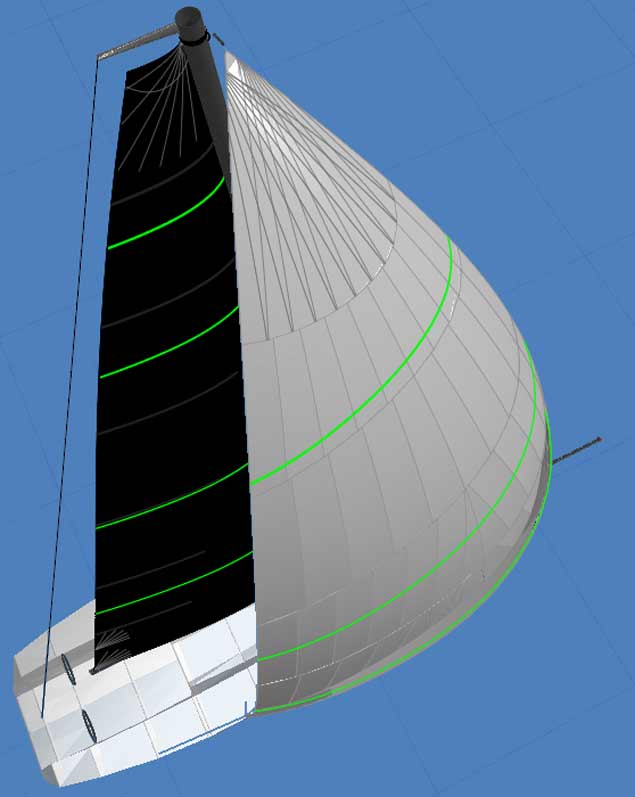

With Sailpack, the designer first creates a 3D model of your boat; from this they can then design the sails to perfectly match your boat. This is absolutely the best way to design sails for any boat - you get to see the overall picture of how the sails work together, and how they fit to the boat. You get to see how the sails fit around the spreaders and the shrouds, and you can set the clew height and sheeting angles. Just ask your sail designer to show you these design files, and you’ll see that you’re getting the very best sails for your boat.

Designing bespoke sails

What we are looking for is a sail plan and sail shapes that put the maximum driving force in precisely the right place to produce a perfectly balanced boat – and with the least amount of drag, too.

Into this equation goes the hull, the keel, the rudder and the sails. Added together, this is called ‘the lead.’

Storm Sails

Storm Sails

Here’s an example: Adding extra roach to your main sail adds pressure at the back of the boat, changing the lead and thus causing drag. The extra roach may produce 1% more power, but at the cost of an additional 3% weather helm – not good! To balance this out, you’ll need to add more headsail area and restore the balance on the rudder. There’s no such thing as a free lunch, and the main, jib, keel and rudder all need to perform in concert – which is why we’ll never design a main on its own without looking at the overall picture of the boat.

In the design file below, you can see that the Code 0 is set half way along the sprit, and not at the end. This is to balance the First 34.7 on a reach, and upwind. If it was, indeed, at the end of the pole, it would produce lee helm, and that will affect how the boat sails upwind. It will also reduce the apparent wind angle, allowing you to sail closer to the wind with the maximum amount of power. Going downwind in heavy airs (25 knots at 135˚ apparent wind angle), you may want to move the tack of the Code 0 to the end of the sprit in order to push the bow down.

There are some basic design moulds we work from: one design, cruising, club racing, racing and high-performance racing. Each of these basic moulds has different default parameters and set up including twist, depth and camber position.

Sail camber position A

Sail camber position A

Here’s another example: most mainsails are designed to have the maximum camber between 38% and 46%, and designers don’t go outside these values. You can tweak this parameter to get the driving force forward, but you have to ensure that you do not close the slot between the main and the jib, as that will decrease the airflow across the sails and slow the boat down.

How the design tools work: data points, green lines and mast bend

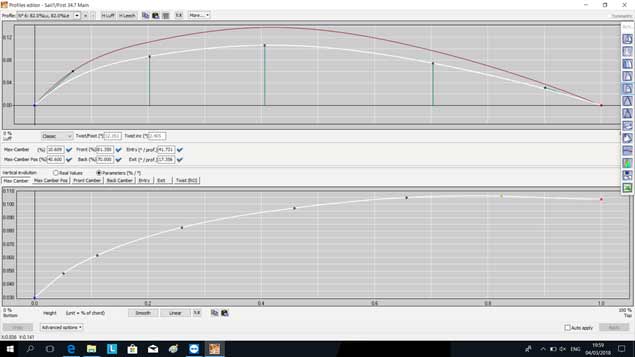

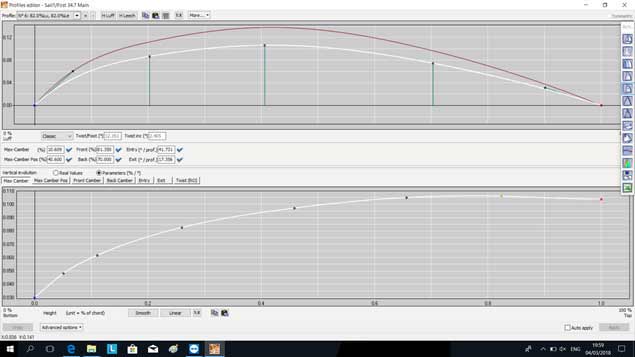

Designing a sail is very much like designing a wing. The two most important numbers are lift and drag. In the Design Editor file below you can see the selection of tools we have to change the shape of the sail.

Sail Shape B

Sail Shape B

You can see the vertical camber bottom profile, or the horizontal camber top profile. In the top view you can see the overall shape of the sail at each section. This is the section at 82% - the top of the sail at the yellow dot. In the bottom view you can see the parameters are in % values and not real values. With Sailpack you can move any of the data points - the black dots on the screen- up or down to make the sail the correct shape (or you can change the values in the boxes if that’s easier). And then take a look at the green line along the luff and the leech of the sail, which you use to make the entry and exit angles smooth. This is a great tool to assist in getting the shape of the sail absolutely right.

Now let’s add mast bend into the equation. The relationship between mast bend and the slot working together needs to be understood when designing the sail. For sailing upwind with the backstay full on you need the luff curve to allow the sail to flatten (but not over-flatten) the sail so that it retains just enough shape to provide power and driving force without closing the slot - which causes drag. When sailing downwind with the backstay off, the static bend allows the sail to deliver maximum available power which goes straight into the boat’s power train.

Sailing downwind

Sailing downwind

Sails: where are we today?

Mainsails have become a lot flatter in recent years due to the invention of moulded sails technology and the availability of stiffer fabrics. Headsail design has come a long way, too. Jibs and genoas are a great deal flatter in the leech with more twist (between 60% and 80% of the leech), and have become very deep and knuckled, creating a better angle of attack at the entry, which both balances the boat and creates a better flow over the sail.

Overlapping genoas haven’t changed quite so much, apart from the shape of the camber which has become a lot smoother and acquired a straighter exit. 3D design tools mean that we can marry the leech to the rig, which you can see in the design file below - as you can see, the leech is really close the spreaders and shrouds giving the max headsail area and balance between the sails.

Asymmetrical spinnakers have become more user-friendly and easier to use. Higher clews help with the leech twist, and improve sheeting angles. A-sails have evolved from being solely reaching sails to becoming running sails as well, making ‘shifting gears’ even easier. In addition, UK Sailmakers have perfected a bungee retractor system that disappears into the luff and the foot when the sail is hoisted, and eliminates the need to ‘band’ sails – a little bit more environmental friendliness!

Flying Jibs

Flying jibs have become a new asset in the arsenal of any racing boat. They are much faster than a code zero up wind. It allows you to sail higher and with a lot more power. There are a few tips here to making this sail work for you. How the flying jib is set is the most import bit of all. Going back to the days of old; the sail has to be set on a flying forestay at a set height so the sheeting angle and you reduce the drag on the overall sail plan.

Flying Jib

Flying Jib

Flying Jib Top View

Flying Jib Top View

Top-down furling gennakers, with a cable in the luff, are especially good news. This sail is easy to deploy and easy to furl, and will never get a twist in it. It’s a sail that transformed offshore racing and has now trickled down to cruising usage. Whether you are pushing hard in a race, or want to leave a sail up overnight while cruising, the ability to furl/unfurl whenever needed is absolutely invaluable.

Top down cuising gennaker

Top down cuising gennaker

Today’s sails are stiffer than they used to be, and that means that twist has become an even more important design factor. Putting twist into the leech of sails means that, as the wind strength increases, they open up quickly and keep the laminar flow over both sides of the sail working properly. Getting the airflow to stick to the back of your sail is vital. A handy tip here is to put your hand on the back leech/clew area of the sail and feel if the airflow is sticking to the sail.

Modern sails have transformed sailmaking and how sails work. It’s part materials, and part design capabilities. UK Sailmakers use Uni-Carbon to build sails that are stiffer, keep their designed shape, and last longer. The sail is now structurally loaded from head to clew, and Uni-Carbon will also hold the load from luff to leech, making the sail able to hold its shape better. It’s a materials advance that has transformed the art of sailmaking, and allows UK Sailmakers to bring you better, faster, sails that last longer.

Sail Pack Viewer

To use Sailpack viewer, please download this link: http://www.bsgdev.com/CMS3/index.php/menuproducts/sailpack-viewer

and then sign in.

Once you get the key code, you can view the attached design files (downloadable below), which are 3D views of a Beneteau First 34.7

They should give you an idea of sail shape and sail design in real time, including the effects of the principal variables - hull, keel, rudder, sails. From this you can see the relationship between all of the items we have been talking about, and how they work as a team together.

And the best tip of all? Talk to your sail designer!

Barry Hayes is a sail designer and product development manager and owner of UK Sailmakers Ireland and is a member of the Board of Directors UK Sailmakers International