In early 2019 the news broke that there was a new “WOW” on the way to Ireland from Lisbon. George Sisk had added a new XP44 to his line of successful racing yachts named “WOW”. Barry Hayes reports on the role of UK Sailmakers Ireland.

Following a competitive bid process; the UK Sailmakers Ireland team was chosen as their sailmaker for the project. We hit the ground running and, having a strong working relationship from the previous WOW campaign, we were able to work closely with George and his team to get as much info about the new boat as possible before her arrival.

Research and Requirements

The first phase of any project is to research the boat you are working with, its behaviour and performance characteristics, and gather the requirements of the owner. This gives us a clear path toward success.

Performance Research

The XP44 is a regular competitor in events throughout Europe, both inshore and offshore. We gathered key IRC data and past race results to give us a picture of where the boat performed best, and what her disadvantages were. We found that reaching, sail handling, and her IRC handicap were key issues which needed to be addressed.

With our polar performance data from other XP44s in hand; we gathered further data from other UK Sailmakers lofts in our network who have raced and made sails for the XP44, and what their overall impression of the boat was. Digesting this experience, and cross-referencing it with our performance analysis data, allowed us to refine our design and optimisation approach for the WOW project.

XP44 Maestro with sails by UK Sailmakers Ukraine

XP44 Maestro with sails by UK Sailmakers Ukraine

Requirements

With a good understanding of the performance characteristics of the new boat, we could focus on compiling the key requirements for the campaign. A major part of this is the events the boat would compete in, who she would be racing, and the prevailing conditions she would be racing in.

These requirements then steer the sail wardrobe development and design as well as the IRC optimisation process.

The main focus for the WOW campaign for 2019 was coastal racing, major offshores, and local DBSC racing. This put usability and straight-line speed at the top of the priority list. It also meant that a significant amount of the off-the-wind sailing the boat would be doing would be tight or broad-reaching as opposed to the deep downwind sailing you would get if the boat was solely focused on inshore windward-leeward course racing.

From our performance analysis, we knew that reaching was one of the boats main weaknesses. This is due to the balance of the boat. When reaching the powerful mainsail needs to be offset by a strong sail force forward of the mast. If this is not done then the boat has a tendency to spin out to windward in gusts rather than accelerating – causing the helm to constantly fight the boat with the rudder. We will talk about our solution to this issue in our sail specification and design later in the article.

We concluded our requirements gather phase with the following initial requirements:

- Optimize performance for light/medium conditions

- Balance helm off the wind

- Maximize usability and simplicity of the sail wardrobe

- Ensure power is controlled in heavy airs downwind

Bowsprit

Early in our discussions, it was decided to fit a longer bowsprit to the XP44. This additional length would give us a better aspect ratio for the spinnaker designs (STL:SPL). It also gave us more option in the forward sailplan of the boat for keeping the helm in balance, discussed further below.

IRC Optimisation

Graham Curran focused on the IRC rating optimisation process. We knew that the boat performed well in the 8-10 knots wind range based on the polars and weight/wetted surface numbers for the boat. Our goal was to maximize this performance range, achieving the best power to weight ratio possible, while optimising the IRC rating for the required sail area.

A major part of this optimisation was the HSA (headsail area). We shortened the LL of the headsails (luff length) as much as possible while maintaining area by pushing out the LP and girths to the maximum we could fit in the foretriangle. This gives maximum benefit of sail area vs IRC penalty while also maximizing the inhauling effect of the jib leech.

This takes a lot of work and several trial certificates to perfect but we had already done a lot of work on the subject with our J109 development the previous winter. With accurate measurements, 3D modelling, and IRC certificates; we knew exactly what we were looking to achieve performance wise vs the final IRC rating.

Sail Wardrobe and Design

In conjunction with the IRC optimisation, Barry Hayes began specifying and designing the sail plan. The first phase of this is accurately modelling the yacht and her sail plan in our 3D design software. We then refine this model throughout the design and optimisation process.

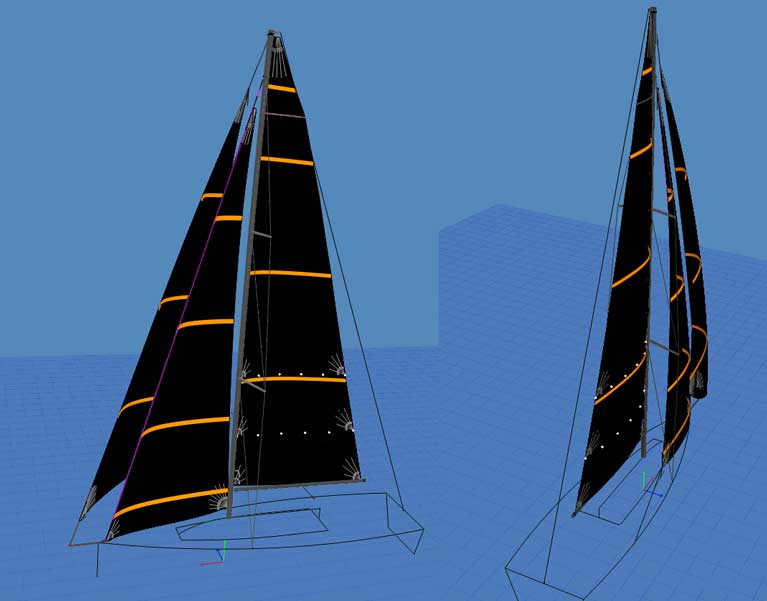

XP44 modelled in real-time 3D. This is the base model for the design phase

XP44 modelled in real-time 3D. This is the base model for the design phase

Reaching Performance

Our performance data clearly showed that there was an issue with the reaching performance of the boat. We had an indication that this was due to the balance of the boat so our first step was to assess the lead of the boat.

MH0 (masthead code zero)

MH0 (masthead code zero)

‘Lead’ is the distance between the centre of effort of the sail plan, usually the Working Sail Area which is the main and fore triangle (CE); and the Centre of Lateral Plane of the hull/foils, (CLP). Both the CE and CLP are approximate positions for the centres of pressure for the sail area and the hull underbody and only really used by yacht designers at the design stages to ensure that the keel and rig positions are well balanced.

This assessment reinforced our understanding of the problem; and what our solution would be.

It was clear that we needed to have a MH0 (masthead code zero) in the inventory. This large code zero helps by pushing the bow down, counteracting the mainsail, and keeping the boat in balance on a reach. The MH0 needs to be a little smaller than maximum to ease sail handling and for use while tight reaching/near upwind work in light airs.

Throughout this design process it became clear there was another performance window to be exploited.

The MH0 is simply too much sail area for tight reaching between 50-70° apparent, depending on the wind speed. This would put the boat back on a full mainsail and headsail, with imbalance remerging as a result. The solution to this issue, and a clear performance gain, was a Flying Jib.

This sail is the same area as the maximum IRC headsail area because, as the name suggests, it measures as a headsail rather than a spinnaker like the code zero. The flying jib is set of the end of WOW’s extended bowsprit, giving greater separation from the forestay and allowing a ‘double-headed’ headsail setup with the J3 set on the forestay foil, and the flying jib outside it. It is also a furling sail – functioning like a furling code zero.

We virtually analysed the flying jib at the 50-70° angles and found a speed increase of approximately 1.2 knots while also keeping the boat balanced.

As the boat comes off the wind she will swap back to the larger MH0. Filling this gap with the flying jib allowed the MH0 to be increased in size, making it more effective downwind. Combining the two sails in the inventory made each sail better than either could be on their own. WOW now had a full effective reaching range from 50° AWA with her flying jib to 130° AWA with the MH0.

Upwind Package

Given the target HSA from our IRC optimisation; Barry moved on to the design of the upwind sail inventory. The designs were based on the polar performance data from the current sail plan which were then refined to allow additional inhauling with a twisted headsail design – allowing greater pointing without sacrificing speed – while maintaining our target IRC rating.

Upwind sailing

Upwind sailing

Handling of the mainsail was a major point of discussion within the team – the mainsail would have to function well both inshore and offshore with usability being paramount. Reef heights, luff tape or slides, full battens or short – all these decisions were influenced by this discussion with the team. We worked off the fact that other XP44s use a luff tape on their mainsail – this proved to be a difficult setup with the external mast track. We spoke with our UK Sailmakers partners who advised us on ideal luff setup and effective reef heights from their experience.

This additional information simplified the decision for the team. The mainsail was specified with two reefs, Antal luff sliders, and short leech battens.

To further optimise the IRC rating we put a small fathead on the mainsail and reduced her P measurement – resulting in a favourable aspect ratio.

Downwind Spinnaker Package

The main concern for the team was boat handling downwind in heavy airs. The XP44 has a bit of a reputation for being a handful when the breeze is up as she doesn’t plane. Solving this issue and getting the best performance from the SPA (spinnaker area) was the last critical step in this design phase.

From running trial certs we found that 190m2 produced the best power to weight ratio with a favourable rating. We worked from this number to determine the size of her working spinnakers.

The A1.5 is a sail made for light air performance. It is designed to work at tight VMG angles in light airs and then rotated once the tack is eased in building pressure. This would be the workhorse of the boat on Dublin Bay.

Downwind sailing

Downwind sailing

As the boat would be rated with three spinnakers the last slot was reserved for a heavy air spinnaker. We design a hybrid A3/A4 sail which we have worked with extensively in the past. It is designed to be an A3 (medium air reacher) when flown from the masthead halyard but doubles as an A4 (heavy runner) when flown from the fractional halyard. The smaller area required for an A3 tied in well with our power management requirement for the heavier air A4. The logic for using the fractional halyard for the A4 is purely for boat handling. The boat does not need the additional power in heavy airs and bringing the hoist down makes the boat more stable and easier to handle.

Sail Testing and Performance Analysis

Once WOW arrived in Dun Laoghaire she was immediately weighed and measured for her new IRC certificate – including the new extended bowsprit.

At this stage, the sails were in production and were soon delivered to the boat to be fitted and tested with Barry and Graham.

The code zero was to fly on a padeye on the bow of the boat, just in front of the forestay, while the flying jib is flown from the end of the bowsprit. Load testing these points, the halyards, and the hardware that holds them is extremely important before ever leaving the dock. It is the safest way to load the boat and give the crew the confidence to take the gear offshore without any doubts in their mind. After several full load tests and adjustments of the bobstay, it was time to go sailing.

Adjusting bobstay tension is when teamwork really shines

Adjusting bobstay tension is when teamwork really shines

One the water we set up all the sails and optimised deck layouts, the run of furling lines, sheets, halyards etc. We then assessed the boats upwind performance by fully loading the Uni-Titanium upwind sails and confirming the rig’s bend characteristics.

Team Approach to Development and Results

We worked closely with the WOW team to bring their concept into reality – it was now time for the new XP44 to go racing. Straight away she was top of the DBSC results pages winning her first Saturday race on the bay. She finishes up her 2019 DBSC season winning the overall Thursday league and, at the time of writing, leading the Overall Saturday series.

Her most notable performance of 2019 was at Kinsale’s Sovereigns cup where she went bow to bow, wave for wave with her bigger sister, the XP50 “Freya”. It was amazing sightseeing these yachts battle off the coast of Cork for the week – with WOW triumphing with three wins from three races.

“As soon as Barry and Graham of UK Sailmakers heard about George’s new Xp 44 WOW coming to the bay, they got to work analysing the best sail package for the boat based on what we intended to do with her. Once the new sails arrived, they were available to set them up and work with us to achieve the best outcome from them. Since then, nothing has been too much for them. The UK team has been available at a moment’s notice to provide solutions to all sorts of problems – from damaged sails to broken parts and even the design and supply of a cockpit tent, as well as the set up and trim of the new sails. In my opinion, the collaboration between WOW and UK Sailmakers has been instrumental in the success of our first season with the Xp 44 WOW. We are looking forward to continuing – and growing – our relationship with the UK Sailmakers Ireland team in 2020 and into the future.” – Gavin Stillman, Boat Captain